Quality

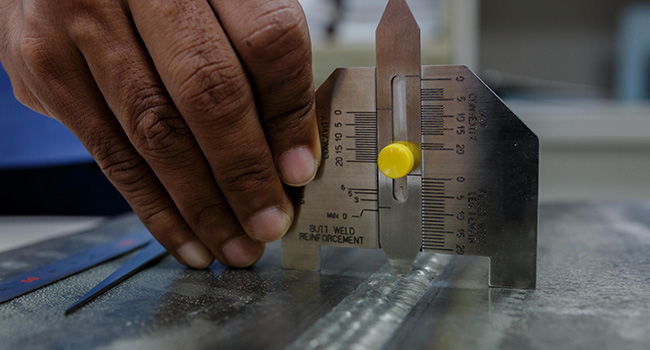

At Canaan Industries, quality isn’t just a goal – it’s our commitment. We believe in an approach where every employee plays a crucial role in ensuring excellence. From the initial stages of design to the final output, we prioritize quality through meticulous attention to detail.

Our quality assurance process involves conducting thorough checks at key production stages, emphasizing prevention over detection. We meticulously review design specifications at project initiation, striving for reliable manufacturing processes that yield consistent results. Moreover, we actively engage in cost-saving measures and share potential benefits with our customers to enhance production efficiency.

Throughout prototype development and final part output, our dedicated team conducts rigorous inspections to ensure that every product produced meets client specifications. Whether it’s laser cutting, forming, bending, or welding, we maintain a steadfast commitment to precision and reliability.

Effective communication with our customers is paramount to our quality policy. We ensure that all jobs are meticulously tracked, fostering transparency and accountability at every step of the process. At Canaan Industries, quality isn’t just a buzzword – it’s ingrained in everything we do. We’re committed to delivering excellence, every time.

|

|